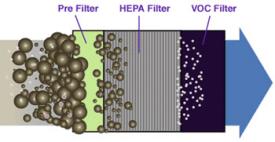

Following guidance from the Centers for Disease Control and Prevention and from the American Society of Heating, Refrigerating and Air-Conditioning Engineers, the University of Nebraska at Lincoln has upgraded the air handling systems in more than 60 buildings. Modifications to 260 air-handling systems included doubling the rate of air exchange and increasing the filtration capacity to remove particles that may carry COVID virus. It is understood that currently filters are in short supply and institutions and commercial enterprises have had difficulty in both converting and maintaining systems.

Following guidance from the Centers for Disease Control and Prevention and from the American Society of Heating, Refrigerating and Air-Conditioning Engineers, the University of Nebraska at Lincoln has upgraded the air handling systems in more than 60 buildings. Modifications to 260 air-handling systems included doubling the rate of air exchange and increasing the filtration capacity to remove particles that may carry COVID virus. It is understood that currently filters are in short supply and institutions and commercial enterprises have had difficulty in both converting and maintaining systems.

The need for regular air exchange and filtration has been clearly demonstrated by the aviation industry in controlled trials. The high rate of COVID incidence in meat packing plants is attributed to concentration of workers in areas with a  low rate of air exchange and low temperature. Following extensive modification of air handling systems in a Tönnies hog plant in Germany, processing resumed with minimal new cases. In the context of meat-packing and poultry processing plants, air exchange, masking, partitions between workstations are obvious measures to reduce infection and will be necessary even after an effective vaccine becomes universally available. Installation of dry hydrogen peroxide air generators in locker rooms, break rooms, offices, and confined spaces can potentially reduce airborne transmission of viral diseases.

low rate of air exchange and low temperature. Following extensive modification of air handling systems in a Tönnies hog plant in Germany, processing resumed with minimal new cases. In the context of meat-packing and poultry processing plants, air exchange, masking, partitions between workstations are obvious measures to reduce infection and will be necessary even after an effective vaccine becomes universally available. Installation of dry hydrogen peroxide air generators in locker rooms, break rooms, offices, and confined spaces can potentially reduce airborne transmission of viral diseases.